Kyotechs 345GC Hydraulic Main Pump - Reliable Performance

Introducing the Kyotechs 345GC Hydraulic Main Pump, a groundbreaking component designed to enhance the efficiency and reliability of your heavy machinery. As a vital part of your excavator's hydraulic system, this main pump ensures smooth operation and optimal performance even under the most demanding conditions. Engineered with precision by Kyotechs, a trusted name in hydraulic technology, this pump delivers exceptional power and durability.

Built with high-quality materials and advanced engineering, the Kyotechs 345GC Hydraulic Main Pump offers unparalleled robustness and longevity. Its innovative design guarantees seamless integration into your equipment, minimizing downtime and maximizing productivity. The precision-crafted components ensure a consistent hydraulic flow, providing your excavators with the necessary force to tackle any job with ease.

Installing the Kyotechs 345GC Hydraulic Main Pump promises to be a hassle-free process, supported by comprehensive instructions and expert customer service. Whether you're in construction, mining, or any industry relying on heavy-duty machinery, this pump is your steadfast partner in maintaining operational excellence.

Trust in Kyotechs to deliver performance and reliability. With our 345GC Hydraulic Main Pump, experience a new level of confidence and productivity in your operations. Invest in quality that stands the test of time and enjoy peace of mind knowing your equipment is powered by one of the best in the market.

Product Image

Our Advantages

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

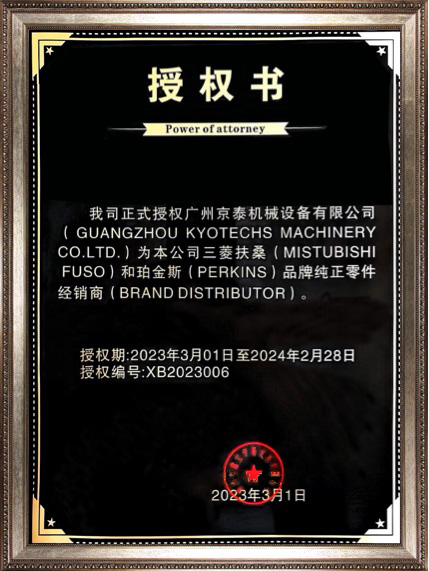

Qualification Certificate

Cummins BETT & INSITE

ISUZU

Perkins

Frequently Asked Questions

What is the reason for abnormal noise from the hydraulic pump?

Abnormal noise may be caused by air entering the system, cavitation, internal component wear or hydraulic oil contamination.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

What causes abnormal noise from the hydraulic pump during operation?

Possible air in the system, cavitation, internal component wear, or oil contamination. Solution: Bleed air from the system, check and fix cavitation sources, replace worn components, replace hydraulic oil.

What liquid should be added to the battery (battery) used normally in the excavator after the liquid level drops? Why?

Distilled water should be added. Because the battery will generate heat during the charging and discharging process, the water will evaporate, and the specific gravity of the electrolyte will increase. After adding distilled water, the specific gravity of the electrolyte can be restored.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Discover Kyotechs' high-quality Excavator Parts 206-60-51132 Solenoid Valve, designed for Komatsu models PC200-6, PC400LC-6, and PC450-6. Optimize your equipment performance with our reliable PC200-6 Solenoid Valve featuring robust construction. Ideal for maintenance and upgrades, ensuring seamless operations for your machinery. Secure this essential component today.

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts 121-1491 Solenoid Valve KWE5K-31 For Caterpillar E307B

Excavator Parts 20G-60-31481 Solenoid Valve For Komatsu PW200-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

High Quality

7/24 Service

Guaranteed Warranty

© 2024 金年会棋牌. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs