High-Quality Undercarriage Parts for Enhanced Stability

At Kyotechs, we offer a full range of high-quality engine assemblies and parts for various excavator models, including Hitachi, Sany, Kawasaki, and more. Our products are built to deliver exceptional performance and durability, ensuring reliable operation in the most demanding conditions.

Our hydraulic pumps and parts are designed to meet the stringent requirements of modern excavators. Whether you need components for Sany, Volvo, Hyundai, or Doosan equipment, Kyotechs has you covered. With precision engineering and rigorous testing, our products deliver reliable performance and long service life.

Kyotechs offers a comprehensive selection of hydraulic motor assemblies and parts for excavators, including Komatsu, Caterpillar, Case, and Kobelco models. Our products are designed to ensure smooth and efficient operation, delivering the power and precision required for demanding excavation tasks.

When it comes to control valve assemblies and parts, Kyotechs has the expertise and products to meet your needs. Whether you need components for Caterpillar, Case, or Kobelco excavators, our offerings are built for durability and precision, guaranteeing optimal performance and precise control.

We understand the critical role that cylinder assemblies and seal kits play in excavator performance. That's why Kyotechs offers a comprehensive range of high-quality components for driving cabin assemblies and inside parts, ensuring reliable operation and long-lasting performance for various excavator models.

Kyotechs provides a complete range of electric parts for excavators, including those from Hyundai, Doosan, and Komatsu. Our products are designed to deliver exceptional performance, reliability, and safety, meeting the sophisticated demands of modern excavator systems.

For the best undercarriage parts for your excavator, look no further than Kyotechs. Whether you need components for mini excavators, pile drivers, hammers, or other equipment, our offerings are engineered for durability, stability, and exceptional performance in the most challenging terrains.

In conclusion, Kyotechs is the go-to source for high-quality excavator parts, offering a comprehensive range of components for various models from leading brands. With a strong focus on performance, durability, and reliability, our products are designed to meet the demands of modern excavation tasks, ensuring seamless operations and maximum productivity.

Remember to contact Kyotechs to explore our full range of excavator parts and accessories, and experience the quality and reliability that have made us a trusted name in the industry since 2009.

What steps should be taken if the excavator engine exhibits low oil pressure?

First, check the oil level and add oil if it's low. Inspect the oil filter for clogs or restrictions, and replace it if necessary. Check the oil pump for wear or damage, and test the oil pressure sensor for accuracy. If these components are functioning correctly, inspect the engine bearings and journals for excessive wear.

What are the symptoms of a faulty hydraulic pump cooling system?

Symptoms of a faulty cooling system include high hydraulic oil temperature, reduced pump efficiency and overheating of the hydraulic system.

Why does the hydraulic pump vibrate excessively?

Possible loose installation, unbalanced pump components, or cavitation.

Solution: Tighten installation, balance pump components, check and eliminate cavitation sources.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

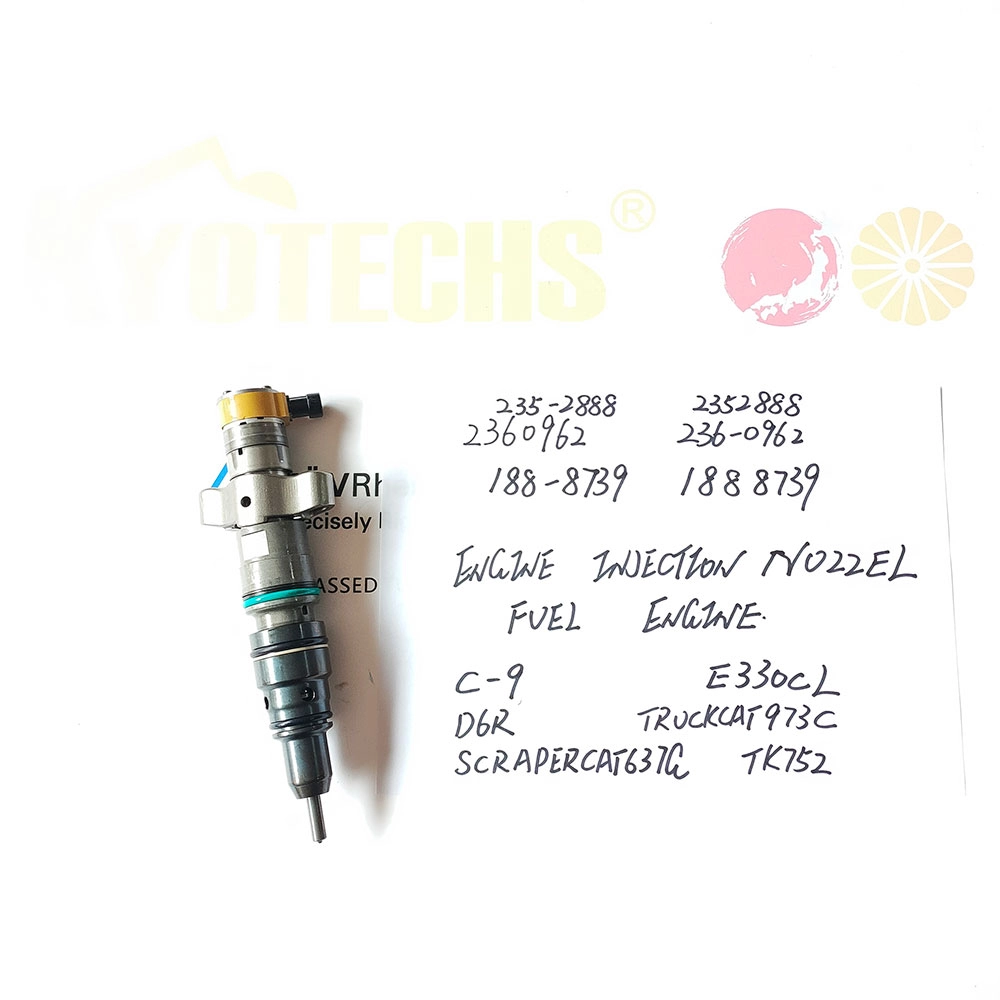

EXCAVATOR SPARE PARTS 236-0962 2360962 10R7224 10R-7224 1888739 188-8739 ENGINE FUEL INJECTOR E330C C-9 D6R

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts 121-1491 Solenoid Valve KWE5K-31 For Caterpillar E307B

Excavator Parts 121-1491 Solenoid Valve KWE5K-31 For Caterpillar E307B

Excavator Parts 20G-60-31481 Solenoid Valve For Komatsu PW200-7

Excavator Parts 20G-60-31481 Solenoid Valve For Komatsu PW200-7

Excavator Parts 20Y-60-11712 Solenoid Valve For Komatsu PC200-5

Excavator Parts 20Y-60-11712 Solenoid Valve For Komatsu PC200-5

Engineering Machinery Parts 15066984 Solenoid Valve For Volvo L90E

Engineering Machinery Parts 15066984 Solenoid Valve For Volvo L90E

Construction Machinery 180584A1 Solenoid Valve For MX80C MX90C

Construction Machinery 180584A1 Solenoid Valve For MX80C MX90C

Excavator Parts 702-21-62600 Solenoid Valve For Komatsu PC200-8MO

Excavator Parts 702-21-62600 Solenoid Valve For Komatsu PC200-8MOhow to set hydraulic pump pressure on 100 hitachi excavator | Kyotechs Guide

how to recalibrate hydraulic pump on cat 321 excavator | Kyotechs Guide

how ic engine and hydraulic pump are connected in excavator | Kyotechs Guide

What are the parts of the undercarriage excavator? | Kyotechs Guide

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

High Quality

7/24 Service

Guaranteed Warranty

© 2024 金年会棋牌. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs