High-Quality PC220-7 Travel Motor | Kyotechs Excavator Parts

Kyotechs is your one-stop shop for top-quality excavator parts, including the popular PC220-7 travel motor. Our extensive range of products includes engine assemblies, hydraulic pumps and parts, control valve assemblies, driving cabin assemblies, electric parts, undercarriage parts, and much more. With our commitment to providing high-quality parts, you can trust us to keep your excavator running smoothly.

Why Choose Kyotech's PC220-7 Travel Motor?

When it comes to excavator parts, quality is paramount. At Kyotechs, we take pride in offering only the best PC220-7 travel motors that are designed to meet the highest standards of performance and durability. Our travel motors are precision-engineered to deliver reliable power and efficiency, ensuring that your excavator operates at its best.

Quality Assurance

At Kyotechs, quality is our top priority. We understand the importance of reliable and durable excavator parts, which is why we thoroughly inspect and test each PC220-7 travel motor before it is delivered to our customers. Our commitment to quality assurance means you can trust that you are getting a top-notch product every time.

Wide Compatibility

The PC220-7 travel motor is compatible with a range of excavator brands, including Hitachi, Sany, Kawasaki, Volvo, Hyundai, Doosan, Komatsu, Caterpillar, Case, and Kobelco. This wide compatibility ensures that our travel motors can meet the needs of various customers, making it a versatile and valuable addition to any excavator.

Superior Performance

Equipped with cutting-edge technology and precise engineering, our PC220-7 travel motors deliver superior performance and efficiency. Whether you are working on a construction site, landscaping project, or any other excavation task, you can rely on our travel motors to provide the power and reliability you need to get the job done.

Reliable Support

At Kyotechs, we are committed to providing exceptional customer support. Our team of experts is ready to assist you with any questions or concerns you may have about our PC220-7 travel motors or any other excavator parts. We are dedicated to ensuring that our customers have a positive experience when shopping with us.

Shop with Confidence

When you choose Kyotechs for your excavator parts, including the PC220-7 travel motor, you can shop with confidence knowing that you are getting top-quality products backed by superior customer service. Our goal is to provide a seamless and satisfying experience for every customer, and we are committed to delivering on that promise.

In conclusion, Kyotechs is your trusted source for high-quality excavator parts, including the reliable PC220-7 travel motor. With our emphasis on quality, wide compatibility, superior performance, and reliable support, you can trust us to meet your excavator part needs. Explore our range of products today and experience the difference that Kyotechs can make for your equipment.

The travel oil motor has just been repaired. The track moves faster at low throttle, but will not move at high throttle. What is the remedy?

This is because the valve plate was over-ground during maintenance and the grinding amount was too much, so the pressure between the valve plate and the cylinder plane is insufficient. At low throttle, the oil pressure is small, and it is not easy to leak between planes; at high throttle, the oil pressure increases, and overflow occurs between planes, causing the track to be unable to move at high throttle. The remedy is to add a gasket to the spring. If it is a butterfly spring, you can add an extra butterfly spring.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

Why is the hydraulic pump pressure insufficient during excavation?

Possible low hydraulic oil level, clogged filter, internal wear, or hydraulic line leakage. Solution: Check oil level and refill, clean or replace filter, inspect and repair leaks, check and replace worn parts.

Why does the exhaust pipe emit blue smoke?

When the engine replaces new piston rings, pistons or cylinder liners, due to the initial poor running-in, it is easy for the engine oil to enter the combustion chamber and burn, producing blue smoke. This phenomenon can generally be gradually eliminated after running for 8-10 hours.

(1) The oil level in the oil pan is too high.

(2) The engine oil in the air filter leaks into the combustion chamber from the intake pipe and burns.

(3) The piston ring is bonded to the piston ring groove by carbon deposits, causing the engine oil to leak into the cylinder and burn.

(4) The piston ring is excessively worn, or when several piston rings are installed, the opening gap has been matched.

(5) The matching clearance between the piston and the cylinder liner is too large.

(6) The piston ring is not elastic enough.

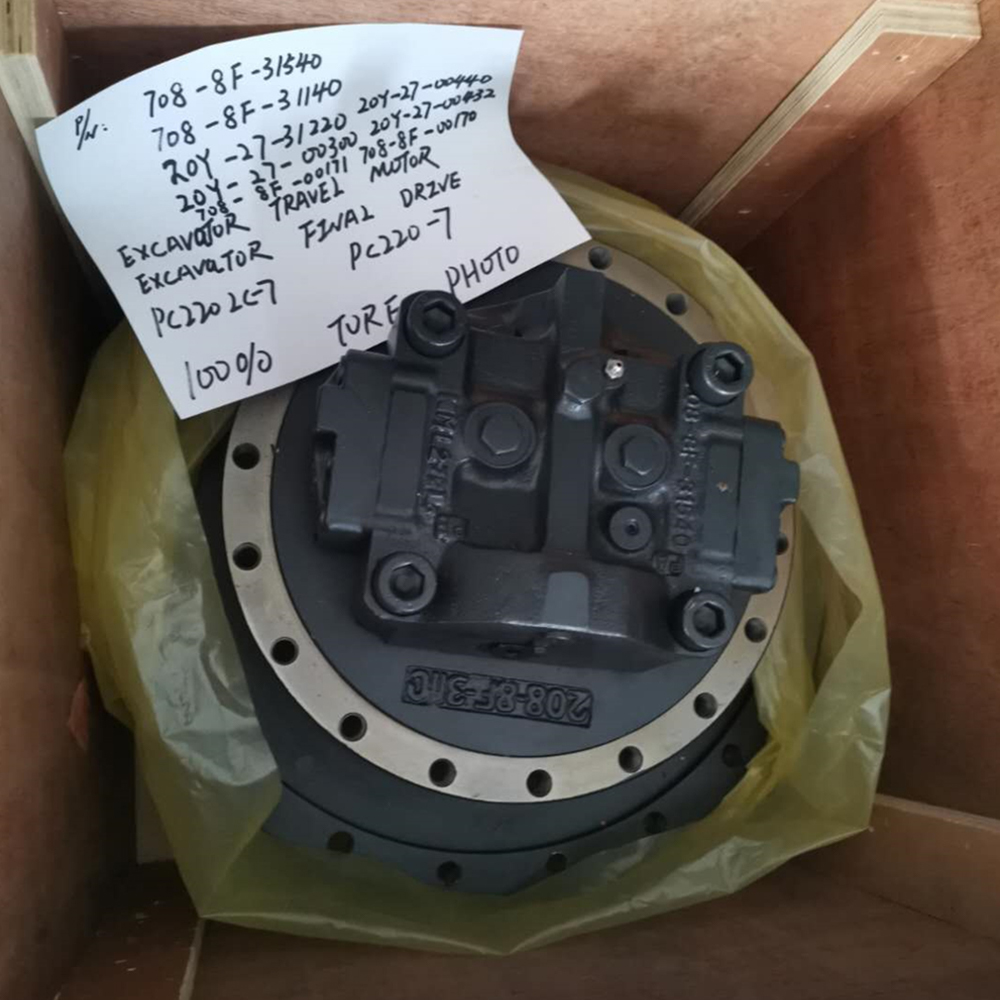

FINAL DRIVE 708-8F-31540 708-8F-00171 708-8F-31140 20Y-27-31220 20Y-27-00300 20Y-27-00440 20Y-27-00170 TRAVEL MOTOR PC220LC-7 PC220-7

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Spare Parts 8-97306421-3 Rocker For Hitachi ZX200-3

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 333-8242 Solenoid Valve For Caterpillar E320D2

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

Excavator Parts 302-3811 Solenoid Valve For Caterpillar 854K 980G

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

High Quality 208-2911 Solenoid Valve For Caterpillar Wheel Loader E825H

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts 206-60-51132 Solenoid Valve For Komatsu PC200-6

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts AP2D28 Piston Pump AP2D28LV1RS7-857-0 For Volvo EC55B

Excavator Parts 121-1491 Solenoid Valve KWE5K-31 For Caterpillar E307B

Excavator Parts 121-1491 Solenoid Valve KWE5K-31 For Caterpillar E307B

Excavator Parts 20G-60-31481 Solenoid Valve For Komatsu PW200-7

Excavator Parts 20G-60-31481 Solenoid Valve For Komatsu PW200-7

Excavator Parts 20Y-60-11712 Solenoid Valve For Komatsu PC200-5

Excavator Parts 20Y-60-11712 Solenoid Valve For Komatsu PC200-5

Engineering Machinery Parts 15066984 Solenoid Valve For Volvo L90E

Engineering Machinery Parts 15066984 Solenoid Valve For Volvo L90E

Construction Machinery 180584A1 Solenoid Valve For MX80C MX90C

Construction Machinery 180584A1 Solenoid Valve For MX80C MX90C

Excavator Parts 702-21-62600 Solenoid Valve For Komatsu PC200-8MO

Excavator Parts 702-21-62600 Solenoid Valve For Komatsu PC200-8MOhow to set hydraulic pump pressure on 100 hitachi excavator | Kyotechs Guide

how to recalibrate hydraulic pump on cat 321 excavator | Kyotechs Guide

how ic engine and hydraulic pump are connected in excavator | Kyotechs Guide

What are the parts of the undercarriage excavator? | Kyotechs Guide

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

High Quality

7/24 Service

Guaranteed Warranty

© 2024 金年会棋牌. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs